Table Of Content

In supply chain modeling, the performance measures (such as those described in Section 4) are expressed as functions of one or more decision variables. These decision variables are then chosen in such a way as to optimize one or more performance measures. There is no second opinion that design has a huge impact on the cost and effectiveness of supply chains. As a result, design and supply chain management teams must come together to produce a product that is built for the selected supply chain. Another helpful design tip to reduce the strain on the supply chain is to transition technology as soon as possible.

The Supply Chain: From Raw Materials to Order Fulfillment

When considering supply chain network design, many organizational leaders think about facility location, warehousing, or plant logistics. To get the best results from SCM, the process usually begins with planning to match supply with customer and manufacturing demands. Companies must try to predict what their future needs will be and act accordingly. This will take into account the raw materials or components needed during each stage of manufacturing, equipment capacity and limitations, and staffing needs. Large businesses often rely on enterprise resource planning (ERP) software to help coordinate the process.

Lean Management Fundamentals

These include the quality of end-to-end coordination, harmonization, and clarity of decision rights; a cross-functional performance system; and employee professional support through social cohesion, mobility, and capability development. We identified companies with superior EBITDA results among their industry peers. We observed that first-quartile performers gave consistently high ratings to a number of organizational factors (described as statements of effectiveness). We tested the correlation between quartile ranks and these factors, using Spearman rank correlation, obtaining a coefficient ρ of 0.83. This event is not just about soaking up knowledge; it's also an unparalleled opportunity for networking and brand amplification.

Company

These features that improve product quality will be costly to develop, but they will usually offset the much higher warranty costs. Product design teams (PDT) can contribute to the selection of the right supply chain management technique for the product by supplying relevant information and adopting various recommended practices during design. Reducing lead times enables a company to work with a smaller inventory at a time. If possible, make sure that your supply chain involves as many local manufacturing partners as possible. It doesn’t mean that you should always turn to your neighbour, but outsourcing to other countries for minimising costs can backfire. Design for supply chain proposes making changes in the design to improve the overall logistical efficiency of a product.

It is because this is what ensures prompt delivery of goods to the customer at the least cost. With the increasing demand for reduced delivery time, companies are looking at ways to optimise their supply chain. A good supply chain design is crucial for a smooth transition from raw materials to finished goods and prompt delivery to customers.

Mapping the Semiconductor Supply Chain: The Critical Role of the Indo-Pacific Region - CSIS Center for Strategic and International Studies

Mapping the Semiconductor Supply Chain: The Critical Role of the Indo-Pacific Region.

Posted: Tue, 30 May 2023 07:00:00 GMT [source]

Some examples of such design changes are size variation, fragility, technology update and infrastructure upgrade. All these changes directly affect the logistics system and need careful planning and smooth execution for minimum disturbance to it. Supply chain management is the process of managing goods and services from the initial stages of manufacturing all the way up to providing after-sales services/warranty for a product. This course is indispensable if you’re considering a supply chain management career and, specifically, the positions of Supply Chain Analyst , Operations Manager , or Logistics Coordinator.

Six Sigma and the Organization (Advanced)

Take the example of a pharmaceutical company, which instituted this role to bridge islands of functional excellence across product groups in demand planning, supply planning, and production planning. The new role, accountable for end-to-end key performance indicators (KPIs) and targets (such inventory days on hand, fulfilment lead times, on-time-in-full service levels), combines cross-functional team management around each value stream. Value-stream managers configure decoupling points for each product group along the multiechelon supply chain, giving guidance and consistency to decision-making across planning processes, and connecting to the commercial organization. They also manage exceptions, generating and analyzing scenarios for optimal decision-making across the different processes that operate in that value stream. Pyke and Cohen (1993) develop a mathematical programming model for an integrated supply chain, using stochastic sub-models to calculate the values of the included random variables included in the mathematical program. The authors consider a three-level supply chain, consisting of one product, one manufacturing facility, one warehousing facility, and one retailer.

Intuitive interface, robust workflows, and easy scenario modeling make supply chain network design more straightforward, faster, and more effective. Historically, organizations haven’t considered variability or risk in supply chain network design. We saw the global consequences of ignoring supply chain resiliency during the pandemic and its aftermath. Companies that didn’t understand the fragility of their supply chains suffered. Supply chain network design is modeling the future state versus the as-is state. It’s an ongoing process to evaluate the end-to-end supply chain to make data-driven decisions using advanced analytics and human knowledge, balancing cost, service, risk, and ESG elements.

Data-Driven Supply Chain Network Design

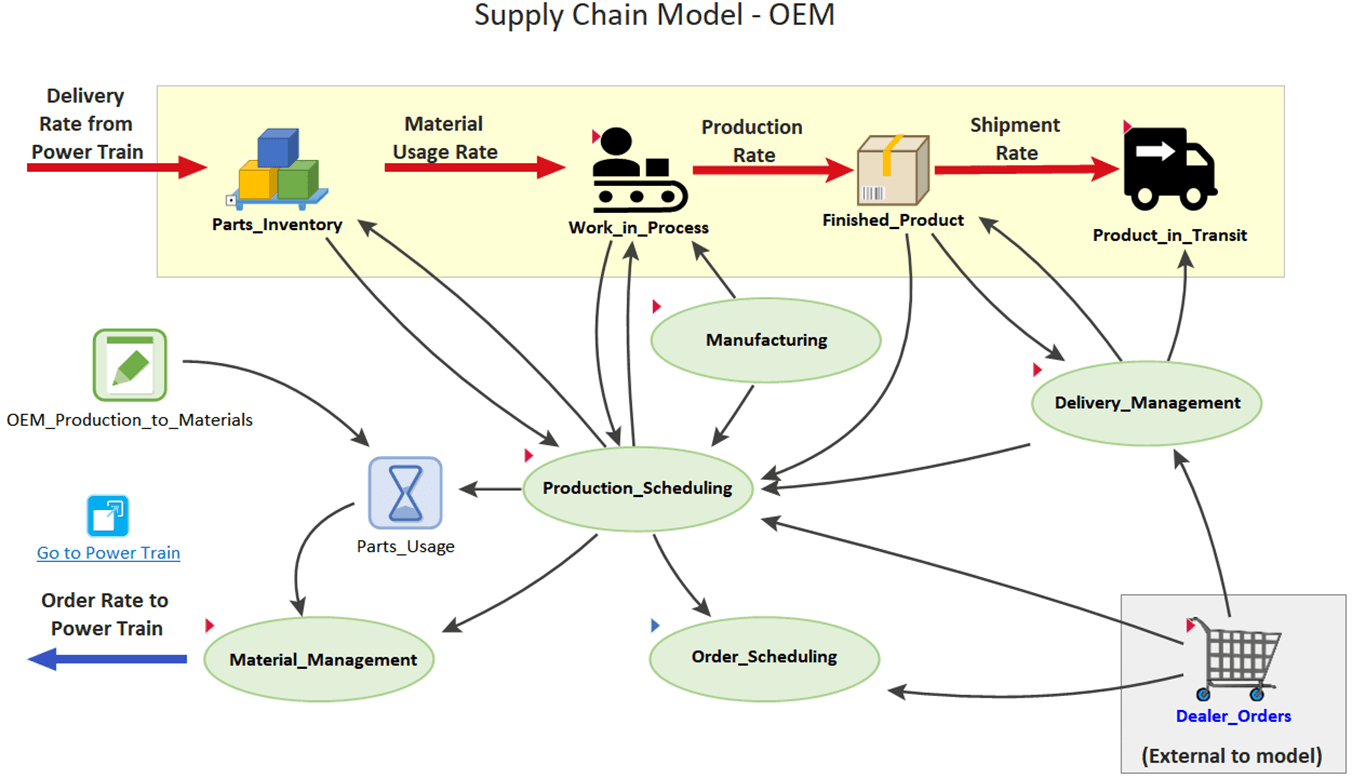

This is largely due to the continuous growth of global market volatility which drives the supply chains to become more flexible and agile, and the less vertically integrated supply chain offers precisely that flexibility. On the opposite direction of vertical integration is vertical disintegration where the supply chain comprises of many independent participating members and the OEM does not have a large extent of vertically integrated consecutive operations. In fact for a vertically disintegrated supply chain, a considerable part of the OEM’s operations are outsourced to the independent external suppliers in order to achieve maximized value-adding and minimized the total cost for the supply chain.

How generative AI in supply chain can drive value - EY

How generative AI in supply chain can drive value.

Posted: Thu, 27 Jul 2023 07:00:00 GMT [source]

How do decisions about the design of supply-chain organizations affect the overall performance of a business? We recently analyzed the supply-chain organizations of more than 50 companies in a wide range of industries in Europe, Asia, and the Americas (see sidebar, “Note on methodology”). We asked about strategic priorities, organizational structures, management practices, and work culture in their global supply chains, aiming to understand choices that correlate with companies’ EBITDA performance.

According to McKinsey Global Institute research, more than half of today’s tasks could be automated by 2055, resulting in process transformations and the implicit need to reskill and upskill workers. The root cause of this could be the fact that only 6 percent of companies have a formal perspective on their organizations’ strategically important skills and competencies. Facing this issue, one consumer-goods company began to revise its performance-management system by aligning KPI definitions across all of its units. Although targets would still be differentiated by market, it designed a system in which the most important metrics were owned by collaborating functions.

No comments:

Post a Comment